Technology series MLH

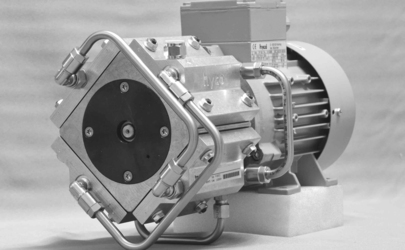

4-cylinder diaphragm pumps with H-linear drive.

The stroke movements of the diaphragms (2 pump heads each, beside one another) in the non-offset diaphragm pump heads opposite, is linear, i.e. up and down in a straight line. No staggering or flexing of the diaphragm as with diaphragm stroke movement caused by eccentric and con-rod drive mechanisms. The H-linear drive thus guarantees a longer service life for the diaphragms.

In the pump housing the eccentric drive shaft for the H-linear drive is separately supported - the H-linear drive does not sit on the motor shaft. This ensures that the motor shaft and the A-side motor bearings are not loaded thus ensuring a longer service life for the mechanical components. The motor shaft is slid into the separately supported eccentric shaft of the H-linear drive as a precision fit and is fastened in place there.

With this H-linear drive, the diaphragms sit above the drive shaft with a smaller offset than with con-rod pumps. In comparison with a con-rod pump, this design results in a more compact solution for the same power. Thermally insensitive external rotor motors (IP00) are the preferred choice for the drive. It is also possible to attach DC motors.

The pump is equipped with patented disc valves made from EPDM. The diaphragms are made from VITON. The interconnection options of the 4-cylinder (parallel, 2-stage in series, or 3-stage) unit allow the final vacuum, the compression pressure and the flow rate to be adapted to the respective requirements by means of flexible hoses.

Features:

- Oil-free and thus pure transportation, evacuation and compressing of gases.

- Quiet and vibration-free, thanks to precise balancing of pump and drive motor.

- Permanent operation possible through optimised cooling and extremely long service life for the diaphragms due to the flex-free, straight-line upwards and downwards movement through the H-linear drive.

- Maintenance-free thanks to encapsulated ball bearings with special grease filling.

- Gas-tight, untested up to max. : 1 x 10-3 mbar x l/s.

- Horizontal and vertical operation possible.

Possible variants:

- Versions with PTFE-coated VITON diaphragms / PTFE-coated EPDM diaphragms / VA valves

- Versions with corrosion-protected gas conducting components, e.g. chemically nickel plated / hard-coated / VA

- Versions with DC motors - please ask. Further special versions on request.

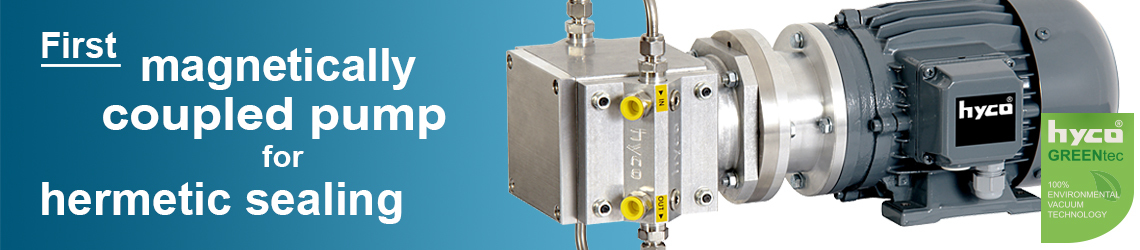

Technologies and enhancements