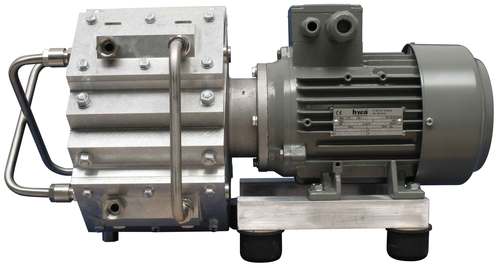

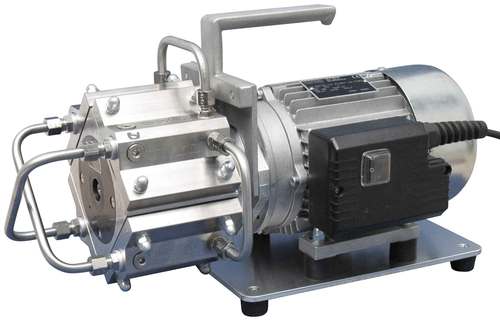

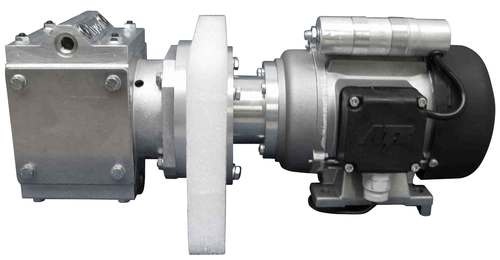

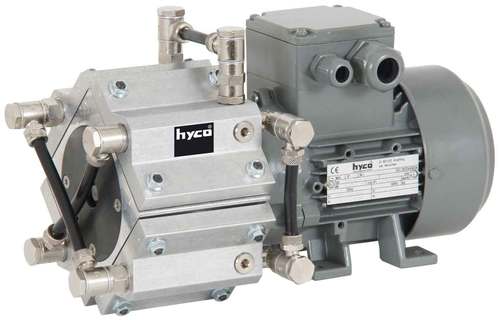

Technology series ML

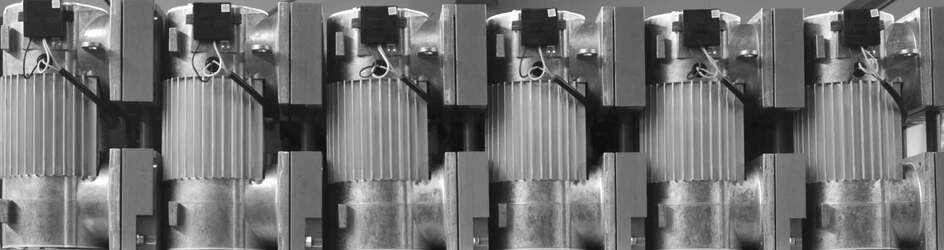

4-cylinder hyco-diaphragm pumps with linear driving mechanism

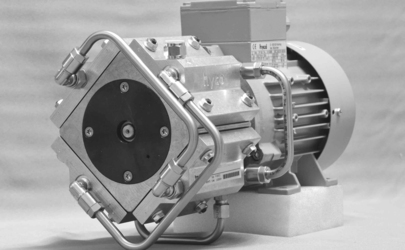

No wobbling and stretching of the diaphragms and therefore no high stress on the diaphragms. The diaphragms are positioned directly over the motor shaft. Thus hyco ML-pumps are more compact in comparison to plunger pumps with comparable output.

With the hyco linear driving mechanism it is possible to install 2 or 4 working cylinders which are positioned directly opposite each other on a cube-shaped flange housing. Each cylinder operates independently. Depending on the intended field of operation whether it shall be for the generation of vacuum or of compression the cylinders have to be positioned parallel or in a row (two- or three-tiered).

A final vacuum of 2 mbar and compression pressures of over 10 bar can be achieved.

The hyco linear driving mechanism is positioned on both sides in a cube-shaped flange housing. There is a toothed ring plug-in coupling on the motor shaft.

The hyco linear driving mechanism achieves more than 20.000 hours of operation without maintenance depending on the medium to be pumped!

Features:

- Oil-free and thus pure transportation, evacuation and compressing of gases.

- Quiet and vibration-free, thanks to precise balancing of pump and drive motor.

- Permanent operation possible through optimised cooling and extremely long service life for the diaphragms due to the flex-free, straight-line upwards and downwards movement.

- Maintenance-free thanks to encapsulated ball bearings with special grease filling.

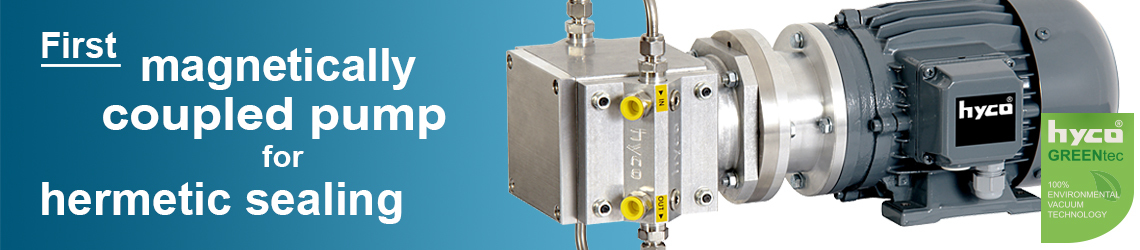

- Gas-tight, untested up to max. : 1 x 10-3 mbar x l/s.

- Horizontal and vertical operation possible.

Possible variants:

- Versions with PTFE-coated VITON diaphragms / PTFE-coated EPDM diaphragms / VA valves

- Versions with corrosion-protected gas conducting components, e.g. chemically nickel plated / hard-coated / VA

- Versions with DC motors - please ask. Further special versions on request.

Technologies and enhancements