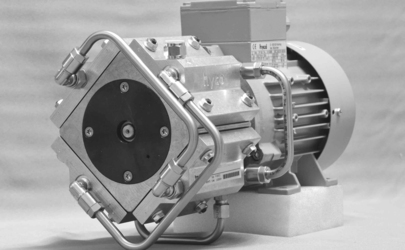

Optimally designed and proven in use

Krailling, Aug 2020: The new assembly hall for the production of hyco vacuum pumps has been presented in the extension of the hyco site in the Kraillinger Innovations Meile for quite some time.

Based on the long experience in pump production, the new assembly lines were arranged, equipped and put into operation for a long time - already on the occasion of the 50th birthday of hyco Vakuumtechnik - efficiently and for employees in a work technically optimized way.

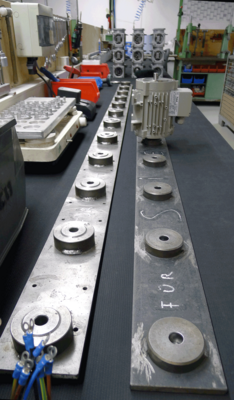

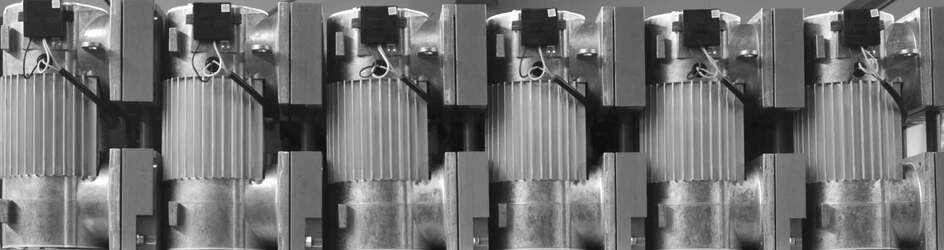

Bright, light, orderly and arranged for different work steps and for different pump sizes, models and customer requirements, production and assembly takes place in the new hall. The ergonomically placed arrangements of components, assemblies and work equipment of the individual workstations continue to ensure that every handle for the assembly of the customer-specific pumps is in place and production routes are kept short. The necessary storage capacity for components as well as finished pumps is provided by the directly connected new storage aisle as well as the already used storage areas.

The new and bright test room for all relevant pump data is directly accessible on the same level. This allows vacuum pumps to be checked and changes to be made in a short time.

For hyco Vakuumtechnik - well known for the production of series and customized pumps - the implemented principle of assembly lines is the basic requirement for the constant high and verifiable quality of the pumps as well as a constant reliable throughput of the pump production in the assembly.

editorial contact:

INGENIEURBÜRO Beatrix Kaufmann-Ludwig

Hausener Str. 1

82131 Gauting

preludio.de

info@preludio.de

pictures:

The new assembly hall of hyco Vakuumtechnik in the Kraillinger Innovations Meile

Insight into the new assembly lines _ 1

Insight into the new assembly lines _ 2

Insight into the new assembly lines _ 3

Picture gallery - small insights and details