Technology series KL

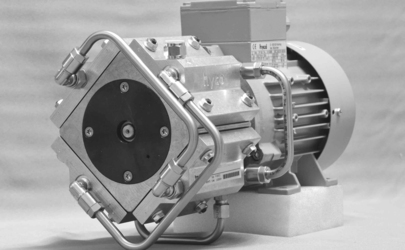

The straight guidance of the piston in the cylinder, between top dead centre and bottom dead centre, ensures that the piston sealing rings are evenly loaded all around. In contrast to tilting movements, this achieves a long service life for the piston sealing rings.

In the flange pump housing the drive shaft is supported on both sides of the linear drive. The force transfer with the drive motor is implemented by means of a slide-on coupling on the pump shaft and motor shaft. Oscillating weights and the counterbalance weight are integrated into the pump-side section of the coupling.

The interconnecting of the cylinder is implemented by means of VA tubes. Note: ML and KL pumps with linear drives can be constructed with 1, 2 and 4 cylinders and as double pumps with up to 8 cylinders.

Features:

- Oil-free and maintenance-free

- Quiet and low-vibration running thanks to precise balancing of pump and drive motor

- Permanent operation possible through optimised coolin

Possible variants:

- AL cylinder with hard-coat layer, or VA cylinder

- Gas-conducting components hard-coated, or made from VA/PTFE

- Special versions for gas temperatures up to +200 °C

- Special versions, gas-tight piston pumps

Technologies and enhancements